tungsten carbide wear parts wear resistance improvement

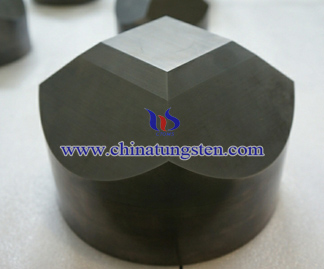

Tungsten carbide wear parts extremely broad scope, mainly steel and other industries use roller ring with a synthetic diamond anvil and pressure cylinder, precision mold, precision optical molds, stamping dies, drawing die, seal rings, pistons, bearings and hardened inserts journal welding, coating materials, etc.

Alloy with high strength, high hardness, high elastic modulus, high toughness and high wear resistance, such as outstanding overall performance. Are widely used in mining areas requiring high wear resistance and oil mining tools, dies, wear parts. tungsten carbide wear properties affect the environment as well as alloys and other factors. tungsten carbide wear parts wear mainly by the microstructure and chemical composition of the alloy decision. tungsten carbide is the main structural parameters: grain size and binder phase content. tungsten carbide wear parts wear also affected by adding boron and other elements.

In the modern scientific and technological development and industrial production, a lot of important machinery and machinery parts in harsh working conditions, such as high speed, high temperature, high pressure, overloading, etc., so mechanical parts due to wear, corrosion and oxidation to form The damage often occurs. Steel damage caused by friction and wear, mostly starting from the surface. The use of surface protection measures to delay and control surface damage, has become an effective way to solve the problem of tungsten carbide wear parts wear. Thus, various mechanical parts wear surface technologies emerged, such as plating, thermal diffusion coating, carburizing, nitriding, alloying, thermal spraying, surfacing, coating (physical and chemical vapor deposition, ion plating), paste hardened layer, high-energy beam (laser or electron beam welding, ion implantation) and the like. RE applications have been successful in YG class, YT class, YW etc. tungsten carbide wear parts, and in the alloy strength, impact toughness increased by 10%, while the wear resistance of tungsten carbide wear parts have been improved .