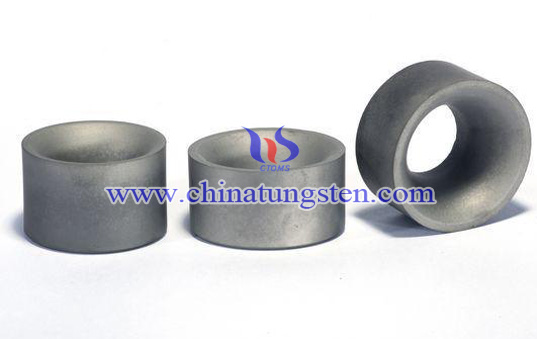

Tungsten Carbide Drawing Dies

In the metal products industry, drawing dies is very important consumable tools. Drawing on the quality of the mold material selection plays a key role in drawing dies. Physical and chemical properties of drawing dies must meet high hardness, impact resistance, abrasion resistance, low friction coefficient requirements.

Tungsten carbide drawing dies cores generally based on tungsten tungsten carbide as raw material to a certain amount of cobalt as a binder sintering. Because cobalt binder tensile strength and micro hardness are very low, so drawing production, the wire and the contact surface is easy to produce the dies hole adhesive wear and abrasive wear, thus affecting the final drawing dies life.

Drawing from the mold core and mold sets of two parts. Selection of tungsten carbide core cobalt tungsten carbide. tungsten carbide drawing dies and mold steel compared with the following characteristics: high abrasion resistance, good polishing, adhesion of small, low friction, low energy consumption, high corrosion resistance, these features make the tungsten carbide drawing dies There are a wide range of processing adaptability, become the most widely used drawing die.

1. YG3X (WC: 97%, Co: 3%): It is a tungsten-cobalt alloy in one of the lowest maximum hardness, strength, wear the best, but the toughness of the worst. Hardness of not less than 92HRC, suitable as pulling thin wire size (0.6mm or less optimal) diameter of 20mm and non-ferrous alloy wire drawing dies.

2. YG3 (C: 97%, Co: 3%): the hardness and wear resistance of a little time and YC3X, but slightly higher toughness. 91HRC hardness of not less than suitable to do the fine wire sizes (1.6mm following best) and non-ferrous metals, alloy wire Tuosi mold.

3. YG6 (C: 94%, Co: 6%) high wear resistance, strength and toughness are good. Hardness of not less than 89.5HRC, suitable as a variety of non-ferrous metal or wire, bar drawing dies.

4. YG6X: strength of 1800MPa, hardness of not less than 91.5HRA, drawing suitable for making the hole diameter is less than 6.00mm wire drawing dies.

5. YG8 (WC: 92%, Co: 8%) of its toughness and impact resistance than YG6 high, but the wear resistance and hardness worse than YG6, hardness of not less than 89HRC, suitable as bars, pipes drawing dies ( 50mm diameter hit below).

6. YG10: strength of 2400MPa, hardness of not less than 88.5HRA, for the production of drawn steel and non-ferrous metal rod and tube drawing dies.

7. YG15: strength of 2800MPa, hardness of not less than 87HRA, for the production of high shrinkage drawn steel bars and pipes.