tungsten carbide wear parts material selection

Tungsten carbide wear parts for the main emphasis on the choice of wear, compression, high rigidity, density and surface finish characteristics. These features primarily cobalt content and grain size of the relevant parameters such as tungsten carbide. Therefore, in accordance with the specific requirements of the parts, the design and selection of low cobalt, cobalt and ultrafine, fine grain alloy.

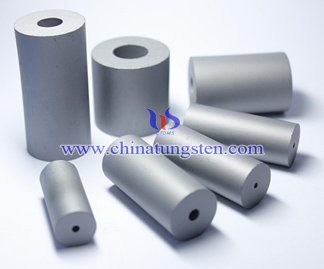

Tungsten carbide wear parts have tungsten carbide tensile modulus, high-pressure cylinders, tungsten carbide valve ball, tungsten carbide bushings, tungsten carbide particles, tungsten carbide and tungsten carbide valve ball stamping dies teeth, etc., for different Wear parts, should choose different types of tungsten carbide.

For drawing steel and nonferrous wire, bar, pipe, profiles tensile modulus, according to wire, tube, bar, section size profiles using different amounts of cobalt alloy. The larger the diameter of the drawn greater the stress, require the use of alloy has good strength and toughness, the same diameter, pipe than the line, bar requires greater use of strength and toughness, and therefore, stretching touch tungsten carbide grades stretch material with a diameter of cobalt content increases. To ensure the quality stretch material and improve the tensile modulus of life, to ensure the use of the strength of the premise, as far as possible to improve the wear resistance, compressive strength and surface finish tungsten carbide, therefore, should be used in ultra-fine, fine, or grain WC-Co alloys.

For the high-pressure cylinder, precision model, lens mold, grinders, and other pass-axis and long plunger tungsten carbide wear parts required to have high rigidity, high elastic modulus, high wear resistance, high-quality finish and fatigue, therefore, should design and selection of superfine alloy. Measuring require abrasion resistance, high precision grinding and high-quality finish, the impact load is very small, and should be designed to use low-cobalt alloy ultrafine or fine grain.