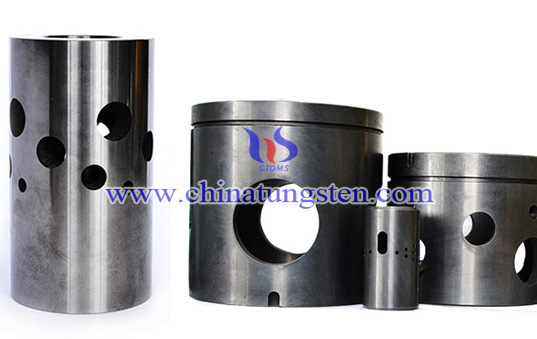

tungsten carbide valve

Polysilicon, coal chemical industry, power plant ash, boiler slag materials such as mud and pipelines, the valve sealing parts not only by the action of sliding friction and wear Sealing components, and withstand high temperature and high hardness of the gas-solid two-phase mixture of high-speed impact, and high pressure fluid caused by the flash and cavitation, which led to corruption, increased valve failure. Therefore, powder transportation and other harsh conditions, wear become an important valve performance assessment indicators.

>Tungsten carbide valve wear resistant characteristics. tungsten carbide high hardness and high stability and other characteristics of the sealing materials ensure excellent wear resistance, to meet the coal, organic silicon (silica fume particles hardness 62HRC) wear special media requirements.

Tungsten carbide valve low coefficient of friction. Cut with tungsten carbide wear pads, not only to extend the service life of high temperature gaskets, given its low coefficient of friction, the overall sintered tungsten tungsten carbide high strength, high hardness, high melting point, high stability, low coefficient of friction, resistance abrasion resistance, and cavitation erosion, corrosion, harsh working conditions for wear and valve seals, improving the applicability of the valve, the valve expanded scope to extend the working life of the valve to ensure that the valve the performance indicators to meet the development needs of the chemical industry.