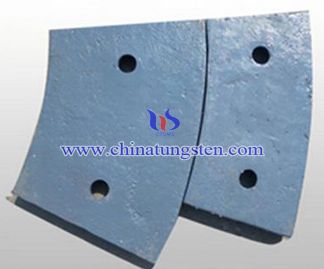

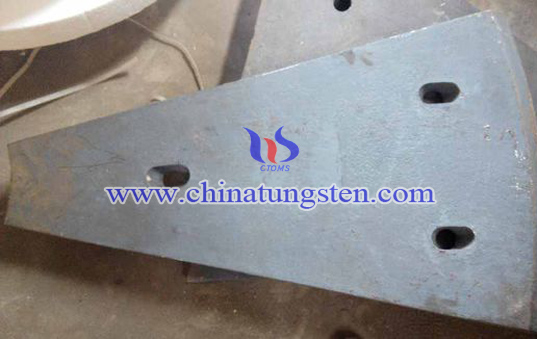

tungsten carbide wear liners

Large-scale blast furnace stream equipment wear-resistant liner has a very demanding, through a variety of materials have been used for comparison, are ideal wear-resistant materials. Than the material hardness and abrasive hardness, abrasive wear performance has a huge impact: When the abrasive hardness is significantly higher than the hardness of the ground material, wear the most intense, hard abrasive wear; on the contrary, is a soft abrasive wear, wear very mild.

In a large blast furnace top equipment through tungsten carbide wear liners daily raw fuel into the furnace up to one million metric tons, which peck highly wear sinter and coke-based, device will cause great erosion and wear, in roof equipment and material feed point by rushing streams at the mill, the use of long-life wear-resistant lining material, in order to reduce equipment downtime. Bell-less top equipment, the main material to withstand erosion and wear parts are: commutation chute, the material at the bottom of the tank, octagonal chute, material flow control valve, the center of the pipe, distribution chute, etc., must be installed in these parts wear-resistant lining board. Liner wear, directly related to the reliability of the roof equipment, the impact of the blast furnace stable production cycle. tungsten carbide wear liners used in small and medium blast, life can be increased by 4 to 6 times. tungsten carbide liner wear more suitable for large-scale blast furnace, large blast furnace and the tank structure is more reasonable to make blanking direction, the smaller the impact angle can give full play to the strengths of tungsten carbide wear liners.

Mosaic tungsten carbide liner wear, can only be made into an arc shape, for reversing the chute, center pipes, distribution chute, and achieved good results. However, tank, valve, etc. non-cylindrical shaped liner, blocks with tungsten carbide uniformly distributed, directly embedded in the cast matrix material. Foundry cast tungsten carbide insert liner, also has high temperature, shock, high strength, high hardness, high wear characteristics, and overall brazing tungsten carbide liner used in conjunction, so type bell-less top equipment life wear parts can be greatly improved.