Tungsten Carbide Wear Parts

Tungsten is mixed with carbon to make a very strong, very resistant material called tungsten carbide. Tungsten carbide is the hardest of all metals. It is about 10 times harder than 18K gold, 5 times harder than tool steel, and 4 times harder than titanium. So it is suit for making cutting tools and wear-resistant tools for metalworking, drilling for oil and gas, mining, and construction. It is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion. In recent years, tungsten carbide has emerged as a superior alternative to steel in many industrial applications.

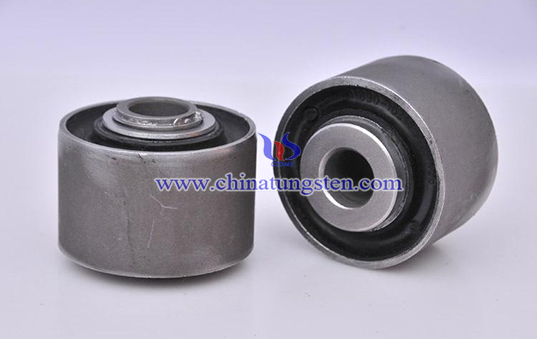

Tungsten carbide wear parts are widely used in industry because of its wear resistance and hardness (9.8 Moe's scale). It opens up new possibilities concerning wear minimization in vary applications through both development of new materials and targeted analysis of application technology. Chinatungsten Online can offering wide range of tungsten carbide wear parts, which are manufactured using high grade raw materials and latest technology.

A large portion of the tungsten volume in tungsten carbide is today used in wear part applications, where there is a wide range of products from the very small to large and heavy products, such as tungsten carbide bush, tungsten carbide pellet, tungsten carbide punch or tungsten carbide button.